NEWS

Shangchun Zhizao empowers the world's largest vanadium electrolyte project to be put into operation, and the fully automatic filling production line sets an international benchmark!

On March 11, the world's largest short-process vanadium electrolyte preparation project with the highest production capacity officially went into operation in Neijiang, Sichuan. This project is not only a milestone for Sichuan Development (Holding) Company in practicing the national "dual carbon" strategy, but also marks a new stage of high-quality development for China's new energy storage industry. As the core equipment supplier of this project, Jiangsu Shangchun Automation Technology Co., Ltd., relying on its independently developed "fully automatic electrolyte ton-barrel filling line + super-high-bay warehouse" integrated solution, provides strong support for the efficient implementation of the project with its industry-leading technical strength, helping to make Sichuan-made vanadium batteries a benchmark for serving the national energy transformation.

The 60,000 m³ annual output short-process vanadium electrolyte preparation project put into production this time adopts a self-developed new generation of short-process vanadium electrolyte preparation technology. The all-vanadium flow battery prepared using this technology has been listed as one of the key technologies promoted in the national "14th Five-Year Plan" Implementation Plan for the Development of New Energy Storage, and can be widely used in grid-side peak-shaving energy storage.

Technology Empowerment: Shangchun Manufacturing Injects "Hard-Core Technology" into the World's Largest Vanadium Electrolyte Project

Vanadium electrolyte, as the core material of all-vanadium flow batteries, its purity and filling accuracy are directly related to the safety and cycle life of the energy storage system. The 60,000-cubic-meter short-process vanadium electrolyte production line put into operation by Sichuan Development adopts the fully automatic electrolyte ton-barrel filling line and intelligent high-bay warehouse provided by Shangchun Manufacturing, overcoming three major industry pain points:

1) Ultra-clean filling guarantees purity: The entire line adopts an active exhaust system and corrosion-resistant materials, effectively sealing out external pollution, and efficiently recovering and processing wastewater, ensuring that the production environment and emission standards reach the top level in the industry;

2) Microgram-level precision control: Relying on decades of accumulation of weighing technology and PID intelligent algorithms, it achieves ultra-precise filling control, with accuracy far exceeding traditional processes, providing reliable assurance for electrolyte purity;

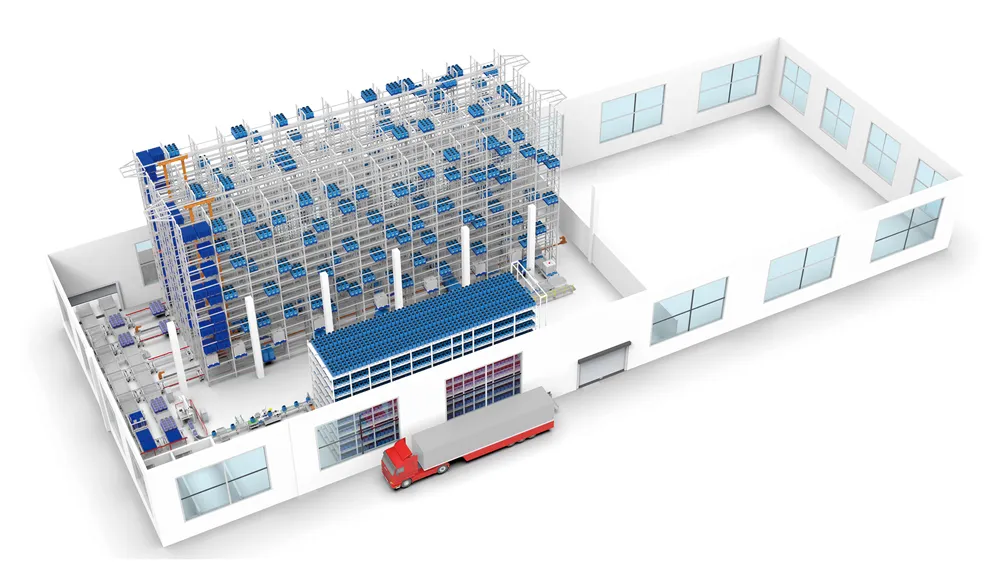

3) Intelligent high-bay warehousing improves efficiency: An innovative "empty barrel warehouse-filling line-high-bay warehouse" integrated architecture is designed, which significantly improves warehousing and filling efficiency with intelligent layout, significantly reducing reliance on manual labor and operating costs.

Intelligent High-Bay Warehousing System

Industry Benchmark: Hard-Core Technology Creates Advantages in Both Semiconductor and New Energy "Dual Tracks"

Shangchun Manufacturing always adheres to the mission of "making chemical manufacturing even purer", building technical barriers in the fields of semiconductor wet electronic chemicals and new energy electrolytes:

1) Currently, the company has experience in supplying products with a Class 100 cleanroom level, the highest in the industry; overcoming the challenges of ultra-clean filling of photoresists and etchants, serving leading enterprises such as Xingfu Electronics and Bokang;

2) Full coverage in the new energy field: From microgram-level weighing of electrolytes to fully automatic filling of ton barrels, the technology adapts to the needs of multiple scenarios such as lithium batteries and vanadium batteries, empowering core customers in the industrial chain such as Shandong Gengyuan, Duofluoromulti, Haikexinyuan, and Xinzoubang Shares;

3) Internationally leading patented technologies: Owns more than 20 core filling patents, rated as "internationally advanced level", with technical parameters comparable to leading European and American companies.

Question

Special Requirements for Wet Electronic Chemical Production Line Equipment

Cleanliness, Purity, Filling Accuracy

Wet electronic chemicals, also known as ultra-clean high-purity electronic chemicals, belong to a branch of the electronic chemical industry. They are various liquid chemical materials used in the wet process of semiconductor microelectronics and optoelectronics (mainly including wet etching, cleaning, developing, and stripping). They are key basic chemical materials in the electronic information industry.

Wet electronic chemicals are characterized by high technical barriers, large capital investment, and rapid product updates and iterations. They are widely used in the semiconductor, display panel, and solar photovoltaic fields.

High-end wet electronic chemicals are mainly monopolized by foreign manufacturers. High-end wet electronic chemicals for semiconductors are mainly controlled by manufacturers in Europe, America, and Japan. In the field of wet electronic chemicals for flat panels, high-generation lines are mainly supplied by Korean manufacturers, and there is a large space for domestic substitution by domestic enterprises.

Special requirements for wet electronic chemical industry equipment:

1) Clean technology—Electronic-grade chemicals are usually used in small quantities, but they have extremely high requirements for environmental cleanliness.

2) Cleaning technology—Extremely high purity requirements, electronic-grade chemicals need to reach ultra-pure and ultra-clean standards.

3) Filling precision control technology—Extremely high economic value and usually used in small quantities, extremely high requirements for filling precision.

Shangchun Benchmark Customers

Strategic Deep Cultivation: Taking "Dual Carbon" as an Anchor, Building a Chinese Business Card for Global High-end Manufacturing

In 2024, Shangchun Manufacturing launched the "New Energy + Semiconductor" dual-engine strategy, comprehensively deploying green manufacturing, and accelerating the production of new bases: The 12,000㎡ intelligent industrial park in Zhonglou District, Changzhou will be put into use in 2025, specially designed for new energy electrolyte and semiconductor etchant production lines, with an estimated annual output value exceeding 500 million yuan;

From vanadium electrolytes to semiconductor photoresists, from Neijiang, Sichuan to the Yangtze River Delta industrial cluster, Shangchun Manufacturing, with the belief of "adhering to the original intention of industrial development and bearing the global mission of green development", continues to break through the technical boundaries of high-end manufacturing equipment. In the future, the company will use "intelligent transformation and digital transformation" as its driving force to accelerate the process of domestic substitution in the new energy and semiconductor fields, and contribute hard-core strength to China's achievement of the "dual carbon" goal and the upgrading of the global industrial chain!

READING