NEWS

On-site Report | Shangchun Manufacturing Showcases at 2025 Shanghai International Agrochemical Exhibition (CACE), Jointly Witnessing the China Solution

From March 17th to 19th, 2025, the China International Agrochemical Equipment and Plant Protection Machinery Exhibition (CACE2025), a top event in the global agrochemical industry, was grandly held in Hall 8.2 of the National Exhibition and Convention Center (Shanghai)! This year's exhibition covered an area of 23,000 square meters, attracting 300+ leading industry enterprises and 90,000+ industry professionals from 120+ countries and regions. The exhibition focused on cutting-edge technologies, advanced production equipment, and green and intelligent solutions for global agrochemical equipment and plant protection machinery, helping the global agrochemical industry to enter a new stage of high-quality development. Shangchun Intelligent Manufacturing, as a leading enterprise in the field of intelligent filling equipment, showcased multiple innovative products, injecting new impetus into the exhibition!

About CACE

CACE2025 is a top exhibition in the global agrochemical equipment and plant protection machinery field. It closely follows the industry's transformation and upgrading needs and aims to promote the reduction and increase of efficiency of pesticides and intelligent manufacturing. The exhibition brought together 300+ exhibiting companies, showcasing cutting-edge technologies and products, including intelligent production equipment, comprehensive solutions, and high-efficiency application machinery. At the same time, the exhibition also held 10+ on-site meetings and attracted 20+ cooperative media reports, providing an efficient platform for the green development and production capacity cooperation of the global agrochemical industry.

Shangchun Intelligent Manufacturing: A Leader in Intelligent Filling

Jiangsu Shangchun Automation Technology Co., Ltd. is a national high-tech enterprise with nearly 30 years of experience in the manufacturing of weighing equipment. It is committed to providing high-precision weighing and filling solutions for the chemical, new energy, and semiconductor industries. The company's products cover weighing and filling needs from 0.01g to 200t and have passed ISO9001 quality management system certification. It has also been awarded the Jiangsu Province "Gazelle Enterprise" certification and the "Intelligent Transformation, Digital Transformation, and Network Connection" service provider title. Relying on the National Intelligent Fully Automatic Filling System Technology Center and the Enterprise Intellectual Property and Standards Center, Shangchun Intelligent Manufacturing continuously innovates technology to provide global users with intelligent and green industrial solutions.

On-site Pictures: Shangchun Intelligent Manufacturing Makes a Stunning Appearance at CACE2025

Showcase of Some Innovative Products from Shangchun Intelligent Manufacturing

Fully Automatic Electrolyte Cleaning and Filling Line

Cleans and fills storage tanks used in the production and transportation of electrolytes, effectively removing external wall contamination.

The main structure uses rust-proof and corrosion-resistant materials, resulting in a long service life.

The entire line is standard-equipped with an active exhaust system to isolate operators from hazardous substances.

It has a built-in waste liquid and wastewater collection and treatment function to meet environmental emission requirements.

Cleaning efficiency is increased by 400% compared to traditional manual cleaning, while labor demand is reduced by 70%, and water consumption is reduced by 50%.

Using high-precision weighing sensors, it lowers enterprise production and environmental costs, improving production efficiency.

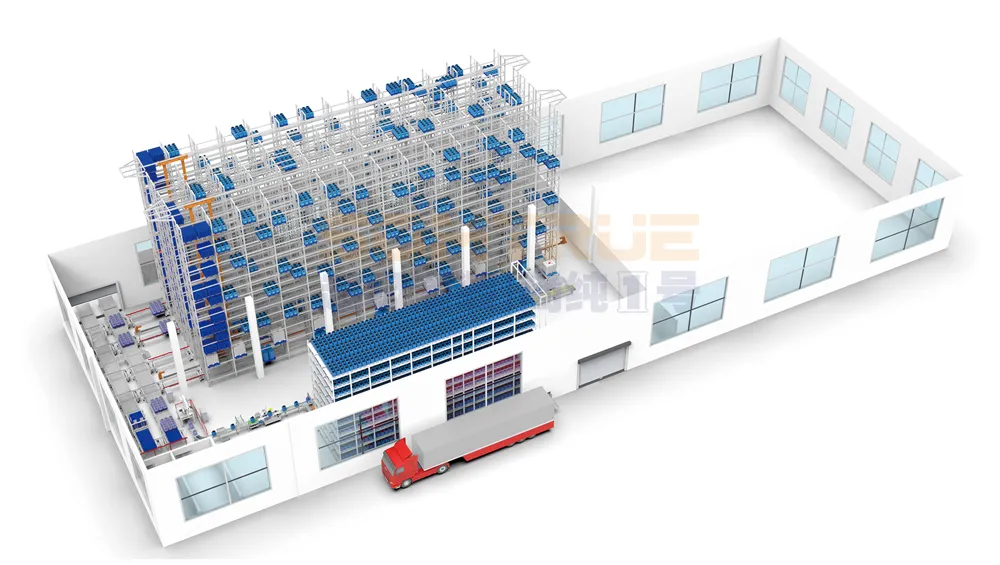

Empty Barrel Warehouse + Filling Line + Automated Warehouse

Compact layout: High space utilization rate, while also having reasonable inspection and maintenance passages.

Large warehouse capacity: Achieves large-capacity storage space while occupying a smaller area.

Shorter conveyor line: Saves energy and conveyor equipment costs.

Separate lines for 200L barrels and IBC barrels, mature structure, short design and manufacturing cycle, short installation and commissioning cycle.

Functionally separated for convenient maintenance; each equipment function is more singular and the performance is more stable.

200L barrels do not need to be placed on pallets, realizing single-barrel filling: The total range is smaller, the accuracy is higher; no visual hole finding is needed, and the speed is faster.

High production capacity: Achieves simultaneous filling of 200L barrels and IBC barrels without mutual interference.

200L-IBC-Fully Automatic Opening, Filling, and Sealing Machine

Quick replacement: The interfaces of the conveying pipeline connections all use quick-release connectors for convenient and quick gun replacement.

Filling mode: Users can control the lifting rate of the spray gun to adapt to products with different foam levels.

Robust structure: Parts in direct contact with materials are made of 304 stainless steel, while others are made of carbon steel, etc.

Interlocking protection: The system is equipped with multiple protections such as barrel collision protection, empty barrel zero zone, tolerance protection, and weighing platform brake lights to ensure operational safety.

Easy operation: One-button filling, net weight/gross weight type, automatic/manual type, etc., functions can be freely switched.

Flexible design: Provides various types of equipment and accessories according to the characteristics of on-site raw materials and container sizes.

Easy installation: Simply fix the equipment to the ground, connect the material pipes, power supply, and gas source, and you can start using it.

Data statistics: Includes weight accumulation and number of times accumulation, and can be connected to a computer for data management (optional).

Filling nozzle: Different filling nozzles can be easily replaced according to different container diameters for convenient operation (optional).

Automatic alignment: The filling ports of circular containers are often eccentric holes. This device can solve the inconvenience of manual alignment (optional).

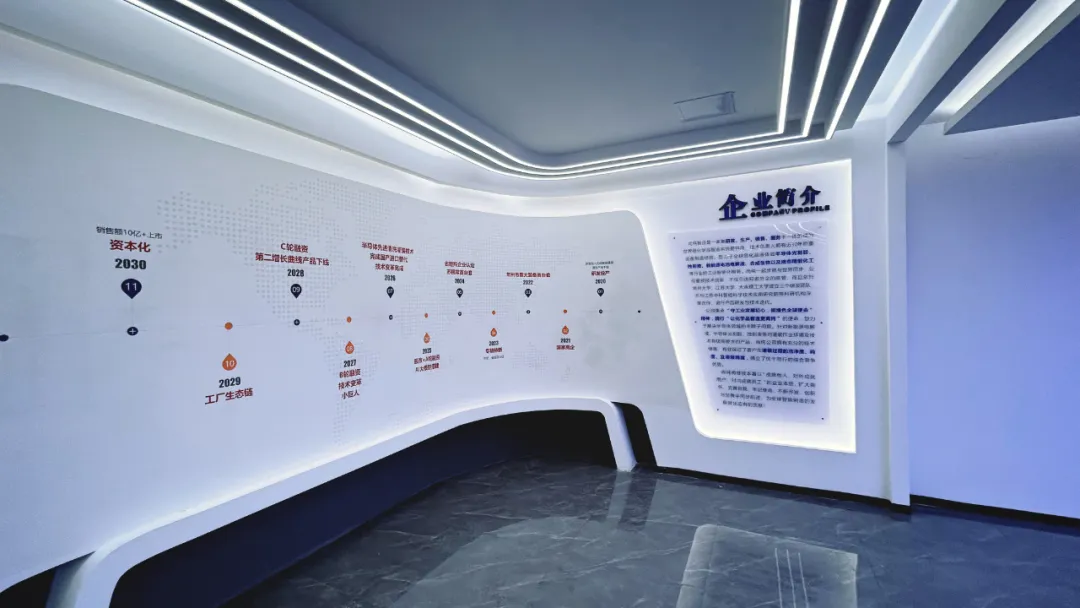

A New Chapter for Shangchun Intelligent Manufacturing: Ushering in a New Era of Intelligent Filling Manufacturing

In 2025, Shangchun Intelligent Manufacturing officially settled in the Xinxin Intelligent Industrial Park in Zhonglou District, Changzhou City, Jiangsu Province, building a 12,000+㎡ intelligent production base. The new park will include a cleanroom, a semiconductor precision etching R&D center, a new energy electrolyte intelligent production line, and an automated warehousing and logistics system. After full production, it is expected to achieve an annual sales revenue of 500 million yuan. Shangchun Intelligent Manufacturing will adhere to the concept of "Upholding the original intention of industrial development and shouldering the global mission of green development" to provide better solutions for the global chemical and high-tech industries.

Exhibition Details:

Location: Hall 8.2, National Exhibition and Convention Center (Shanghai)

Time: March 17-19, 2025

Booth No.: A02

READING